Best selling Pliers accessories from Rothenberger

On this page you'll find a ranking of the best Rothenberger products in this category. To give you a quick overview, we've already ranked the most important information about the products for you.

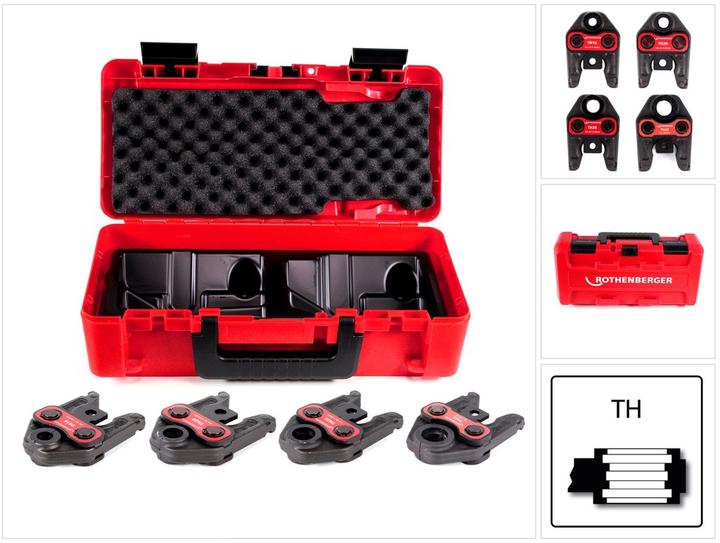

1. Rothenberger Press jaws ROMAX® Standard Set TH 16-20-26 mm

Rothenberger Press Jaws Type TH

The standard press jaws from Rothenberger, known for their proven material and manufacturing quality, are exceptionally stable and durable. They are used for pressing fittings with a diameter of up to 40 mm (for plastic systems) or 54 mm (for metal systems). They are compatible with all pressing machines that have a corresponding jaw holder and a constant axial thrust force of 32 to 34 kN (including ROMAX 3000, ROMAX PRESSLINER ECO, and ROMAX AC ECO).

System-Compliant Pressing

The Type TH press jaws are suitable for various systems.

Made from High-Strength Special Steel

The press jaws are made from forged special steel and are highly durable. The material is hardened using a special process and is characterized by high elasticity and stretchability. The long-term corrosion protection ensures that even frequent and tough construction site use cannot harm Rothenberger's pressing jaws.

Safe and Accurate Pressing

The precision-manufactured contour of the pressing jaw ensures optimal and secure pressings. The 3-bolt synchronization mechanism features synchronous operation of the pressing levers, allowing for very precise work. In addition to its great stability and durability, it has another advantage: the jaw can be opened with a single finger.

2. Rothenberger Press jaw set standard M15-22-28

Press Jaw Set Standard M15-22-28

The Rothenberger press jaws, made from proven materials and manufacturing quality, are suitable for system-compliant crimping of fittings made from metal or plastic systems. The application of a special hardening process, the Dura Lazr Tec technology, along with partial laser hardening, enables precise and secure crimping while simultaneously increasing durability. As a result, wear is minimized, and there are 100% more crimp cycles compared to the previous model. Additionally, long-term corrosion protection supports the longevity of the press jaws. With the use of a high-strength special steel, the press jaws are compatible with all pressing machines that have an axial thrust force of 32 - 34 kN.

3. Rothenberger Pressbackenset Standard SV42-54

For this product, you will receive 11 ROTHENBERGER bonus points.

Product description: The precise pressing jaw made from proven material and manufacturing quality, designed for system-compliant crimping of fittings for metal systems.

Application advantages: DURA LAZR TEC process - partial laser hardening enables the highest degree of hardness at highly stressed points. This results in minimal wear and high contour fidelity. In combination with the forged, highly durable, and flexible special steel, the new generation of pressing jaws achieves 100% longer durability compared to its predecessor. The 3-bolt synchronous mechanism allows the pressing jaw to be opened with one finger. Precision-crafted contour for optimal and secure crimping.

Field of application: The standard pressing jaw set is suitable for use with the ROMAX 4000, ROMAX 3000 AC, and ROMAX AC ECO pressing machines with constant axial thrust. The pressing jaw is perfect for crimping in new construction, for renovation work, as well as for maintenance of metal systems.

Features: Pressing jaw contour: SV.

4. Rothenberger Presavimo galvų rinkinys Standard TH16-20-26-32mm

For this product, you will receive 12 ROTHENBERGER bonus points. More information can be found in the product description. Suitable for ROMAX 4000, ROMAX 3000, ROMAX AC ECO, as well as common pressing machines with constant axial thrust (32-34 kN) and compatible jaw holders.

Application advantages: The DURA LAZR TEC process with partial laser hardening allows for the highest hardness level at highly stressed points. This results in minimal wear and high contour fidelity. In combination with the forged, highly durable, and flexible special steel, the new generation of pressing jaws achieves 100% longer durability compared to its predecessor. The 3-bolt synchronous mechanism allows the pressing jaw to be opened with one finger. Precision-manufactured contour for optimal and secure press fittings.

Field of application: The ROTHENBERGER standard pressing jaw set with contour TH and nominal sizes of 16-20-26-32 mm is ideally suited for system-compliant pressing of fittings for plastic pipe systems.

Features: Pressing jaw contour: TH.

5. Rothenberger Presavimo galvų rinkinys Compact M15-18-22-28mm

Suitable for grouting system fittings made of metal and/or plastic. Long-term corrosion protection. Suitable for all pressing machines with an axial force of 19 kN.

Rothenberger Presavimo galvų rinkinys Compact M15-18-22-28mm

6. Rothenberger Set of press heads standard U16-20-25-32mm

For this product, you will receive 12 ROTHENBERGER bonus points. More information can be found in the product description. Suitable for ROMAX 4000, ROMAX 3000, ROMAX AC ECO, as well as common pressing machines with constant axial thrust (32-34 kN) and compatible jaw holders.

Application advantages: The DURA LAZR TEC process with partial laser hardening allows for the highest hardness level at highly stressed points. This results in minimal wear and high contour fidelity. In combination with the forged, highly durable, and flexible special steel, the new generation of pressing jaws achieves a 100% longer lifespan compared to its predecessor. The 3-bolt synchronous mechanism allows the pressing jaw to be opened with one finger. Precision-crafted contour for optimal and secure press fittings.

Area of application: The ROTHENBERGER standard pressing jaw set with the U contour and nominal sizes of 16-20-25-32 mm is ideally suited for system-compliant pressing of fittings for plastic pipe systems.

Features: Pressing jaw contour: U.

7. Rothenberger Press jaws ROMAX® Standard Set M 15-18-22-28 mm

Rothenberger Press Jaws Type M

The standard press jaws, made from Rothenberger's proven material and manufacturing quality, are exceptionally stable and durable. They are used for pressing fittings with diameters up to 40 mm (for plastic systems) and 54 mm (for metal systems). They are compatible with all pressing machines that have a corresponding jaw holder and a constant axial thrust force of 32 to 34 kN.

System-compliant pressing

The Type M press jaws are suitable for the Mapress system, among others.

Made from high-strength special steel

The press jaws are made from forged special steel and are highly durable. The material is hardened using a special process and is characterized by high elasticity and stretchability. The long-term corrosion protection ensures that even frequent and tough job site use cannot harm Rothenberger's pressing jaws.

Safe and precise pressing

The precision-manufactured contour of the pressing jaw ensures optimal and secure pressings. The 3-bolt synchronization mechanism features synchronized operation of the pressing levers, allowing for very precise work. In addition to its great stability and durability, it has another advantage: the jaw can be opened with one finger.

8. Rothenberger Press jaw ROMAX® Compact TH18 mm

Rothenberger Press Jaws Type TH

The Compact press jaws, made with Rothenberger's proven material and manufacturing quality, are exceptionally stable and durable. They are used for pressing fittings with a diameter of up to 40 mm (for plastic systems) or 28 mm (for metal systems). They are compatible with all pressing machines that have an appropriate jaw holder and a constant axial thrust force of 19 to 21 kN.

System-Compliant Pressing

The Type TH press jaws are suitable for various systems.

Made from High-Strength Special Steel

The press jaws are made from forged special steel and are highly durable. The material is hardened using a special process and is characterized by high elasticity and stretchability. The long-term corrosion protection ensures that even frequent and tough construction site use does not affect Rothenberger's pressing jaws.

Safe and Accurate Pressing

The precision-engineered contour of the pressing jaws ensures optimal and safe pressings. The 3-bolt synchronization mechanism features synchronous operation of the pressing levers, allowing for very precise work. In addition to its high stability and durability, it has another advantage: the jaw can be opened with a single finger.

9. Rothenberger Pressbackenset Standard BE16-20-26

For this product, you will receive 11 ROTHENBERGER bonus points.

Product description: The precise pressing jaw made of proven material and manufacturing quality, designed for system-compliant crimping of fittings for metal systems.

Application advantages: The DURA LAZR TEC process - partial laser hardening allows for the highest degree of hardness at highly stressed points. This results in minimal wear and high contour fidelity. In combination with the forged, highly durable, and flexible special steel, the new generation of pressing jaws achieves 100% longer durability compared to its predecessor. The 3-bolt synchronous mechanism enables the pressing jaw to be opened with one finger. Precision-crafted contour for optimal and secure crimping.

Field of application: The standard pressing jaw set is suitable for use with the ROMAX 4000, ROMAX 3000 AC, and ROMAX AC ECO pressing machines with constant axial thrust. The pressing jaw is perfect for crimping in new construction, for renovation work, as well as for maintenance of metal systems.

Features: Pressing jaw contour: BE.

10. Rothenberger Press jaw ROMAX® Compact TH20 mm

Rothenberger Press Jaws Type TH

The Compact press jaws, made with Rothenberger's proven material and manufacturing quality, are exceptionally stable and durable. They are used for pressing fittings with a diameter of up to 40 mm (for plastic systems) or 28 mm (for metal systems). They are compatible with all pressing machines that have an appropriate jaw holder and a constant axial thrust force of 19 to 21 kN.

System-compliant pressing

The Type TH press jaws are suitable for various systems.

Made from high-strength special steel

The press jaws are made from forged special steel and are highly durable. The material is hardened using a special process and is characterized by high elasticity and stretchability. The long-term corrosion protection ensures that even frequent and tough construction site use cannot harm Rothenberger's pressing jaws.

Safe and precise pressing

The precision-manufactured contour of the pressing tool ensures optimal and safe pressings. The 3-bolt synchronization mechanism features a synchronous operation of the pressing levers, allowing for very precise work. In addition to its great stability and durability, it has another advantage: the jaw can be opened with a single finger.